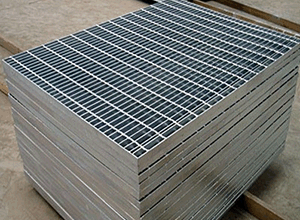

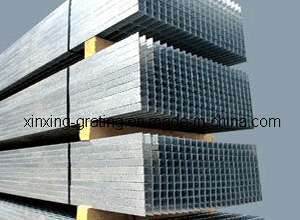

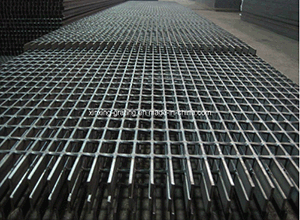

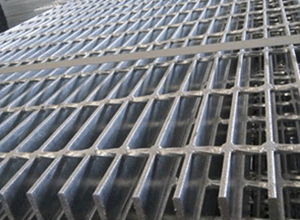

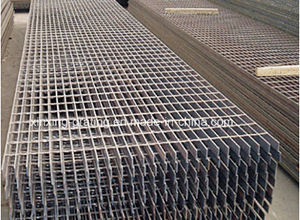

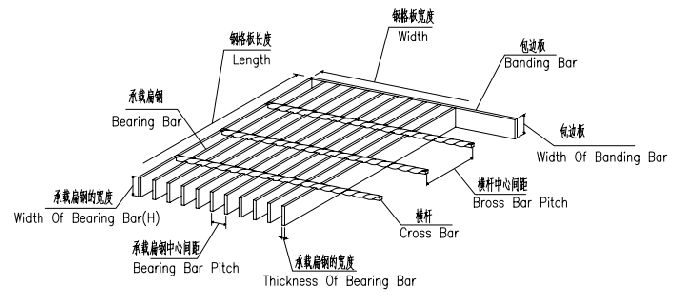

Steel grating is basically consist of Bearing bar and Cross bar by automatic press welding machine as following chart:

Steel gratings are usually made of carbon steel and stainless steel. They are generally used as industrial platform, maintenance platform, stair treads, rain-proof sunshade, fences and trench covers. Widely used in the industry of power plant, oil refineries, petrochemistry, chemical plant, water and waste treatment plant, ship-building, offshore projects and civil construction (like roads, park) ., etc.

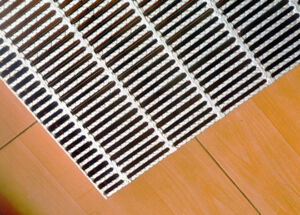

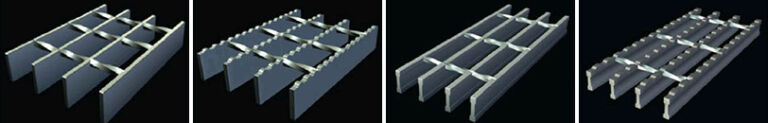

Plain type, Serrated type, I Type and Serrated I type steel gratings are 4 basic kinds of gratings.

| Bearing Bar (width * thickness) | 19*2,19*3,20*2,20*3,20*5,25*3,25*4,30*5,40*5,50*5……..100*10,150*10mm |

| Bearing Bar Pitch (mm) | 12.5, 15, 20, 25, 30, 34.3, 35.3, 40,41.25, 50, 60…(30, 40 mm are recommended) |

| Cross Bar Pitch (mm) | 38.1, 50, 76.2, 100, 101.6 .(50, 100 mm are recommended) |

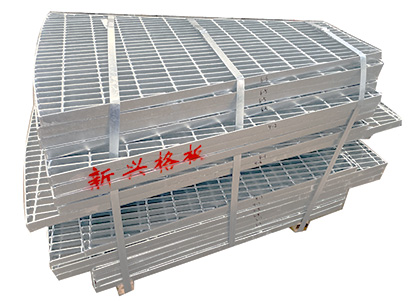

| Surface Treatment | Black/Untreated (U), Hot dip galvanizing (G), Painting (P) |

Material

Mild steel, Stainless steel

Surface Treatment

Untreated, Painting or Hot DIP Galvanized.

| Country | Steel Grating Standard | Galvanization Standard |

| China | YB/T4001-1998, YB/T4001-2007 | GB/T 13912 |

| USA | ANSI/NAAMM-MBG531 | ASTM A123-89 |

| UK | BS4592-2006 | BS 729 |

| Australia | AS1657-1992 | AS/NZS 4680, AS1650 |