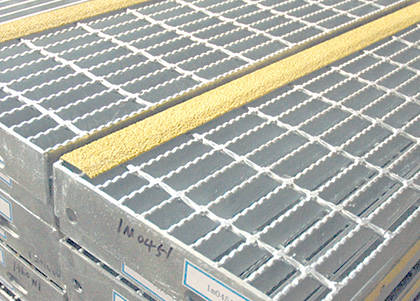

The Classificating of Stair Treads

| Model | Characteriatics of structure |

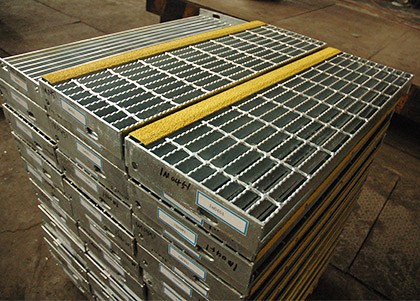

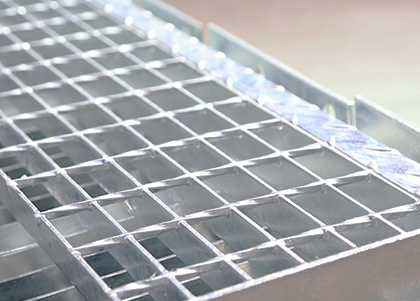

| WT1 | WT1 which is applicable for welding, both aidas are edged with flat bars of which the haight is same with the bearing flat bars and the thickneas is 5mm, without nosing. |

| WT2 | WT2 which is applicable for bolting, both sides are edged with 65×5 flat bars and are punched , without nosing. |

| WT3 | WT3 which is applicable for welding, both aidas are edged with flat bars of which the height is same with the bearing flat bars and the thickness is 5mm, with a nosing of which the thickness is 3mm and the plate is bended and with pattern of lentil shape. |

| WT4 | WT4 which is applicable for bolting, both sides are edged with 65×5 flat bars and are punched, with nosing of which the thickness is 3mm and the plate is bended and with pattern of lentil shape. |

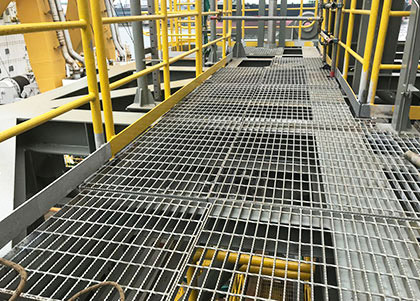

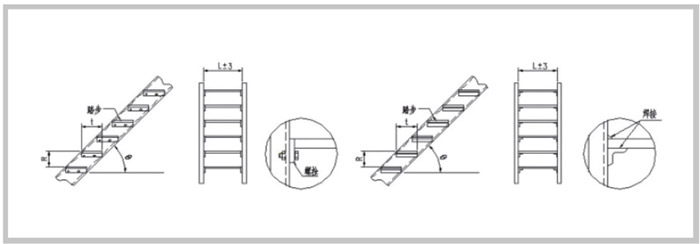

The Connection Type of Tread And Beam

Common Sizes of Treads

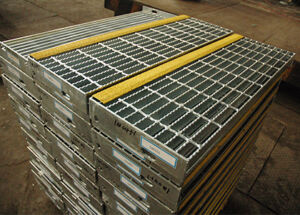

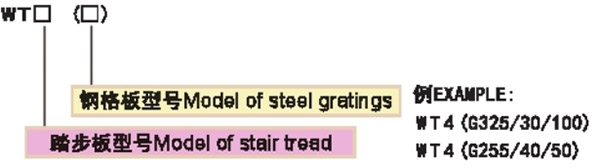

The Xinxing Treads can be made of any kind of steel gratings. The model of gratings may be selected as parthe table of safety load and deflection.

● The stait treads of various sizes can be manufactured by using any type of gratings according to the corresponding stairs. The usual widths of staira (which correspond to the lenght of treads) are 700mm, 600……..100*10,150*10mm, 900……..100*10,150*10mm, the minimum width is 600mm, and the maximum width shall not be more than 1200mm.

● In order to enture the quality, the widh of stair treads recommended in the flowing table shall be used, for example, the thickness of bearing flat bars is 3mm and the end number of corr esponding width shall be corrected to 3.

| Model | Pitches Between Flat Bearing Bars | The Width of Treads(……..100*10,150*10mm)(including the nosing) | ||||||

| WT1-WT4 | 30 | 125 | 155 | 185 | 215 | 245 | 275 | 305 |

| WT1-WT4 | 40 | 125 | 165 | — | 205 | 245 | 285 | 325 |

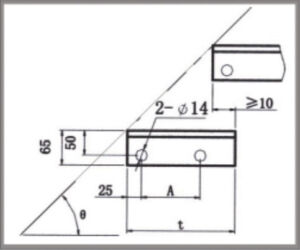

The dimansions of in stallation holes of stair treads which are applicable for bolting shall conform to the customers’requirement. Without requirement,the dimensions shall conform to the following table:

Note: The installation holes at the back of treads mayalso be 25×14 oblong holes bore for the convenianca of instalation.

| T(the recommended width) | 125 | 155-185 | 215-245 | ≥275 |

| A | 45 | 75 | 100 | 150 |